Introduction

Warehouse optimization is a crucial factor in enhancing business operations and driving growth in the logistics sector. From effective inventory management to strategic technology integration, warehouses face numerous challenges that require expert advice and solutions.

This article explores the importance of warehouse optimization, best practices for implementing it, the role of data analytics in decision-making, and strategies for streamlining warehouse operations. By delving into these key areas, businesses can gain valuable insights and recommendations to navigate the complexities of modern warehouse management successfully.

Understanding Warehouse Challenges

Warehouse consulting is pivotal in enhancing business operations by identifying and resolving common challenges faced by warehouses. Effective inventory management, streamlined processes, and technology integration are key to boosting efficiency and growth.

For instance, Office Depot's partnership with Zebra Technologies for the Modern Store digital transformation project, showcased at the NRF big retail show, has significantly improved operational efficiency. The deployment of Zebra's Workcloud Task Management software across 1,500 stores has empowered 13,000 store associates to prioritize tasks, resulting in a remarkable 90% task completion rate and a 42% increase since the software's implementation.

This demonstrates the profound impact of integrating advanced technologies in warehouse management. Similarly, the OneAstec initiative, facilitated by PwC's community of solvers, centralized disparate ERP systems into a unified platform, optimizing supply chain, inventory, and finance data management.

This centralization provided a 'source of truth', standardizing processes and enhancing decision-making capabilities. As the demand for warehouse automation surges, with Interact Analysis predicting a return to double-digit growth in automation revenue by 2025, the focus shifts towards digital upskilling of existing workers over new hiring. This trend underscores the importance of integrating technology and upskilling personnel to navigate the complexities of modern warehouse operations successfully. In summary, addressing warehouse challenges through technological solutions and strategic management not only streamlines inventory control but also fortifies the entire supply chain, underscoring the necessity for warehouses to adapt to an increasingly digital landscape.

The Importance of Warehouse Optimization

The landscape of warehousing is rapidly evolving, with automation playing a pivotal role in reshaping operations. The story of Europris and its partnership with Swisslog highlights a remarkable transformation, where six disparate warehouses were amalgamated into a single, automated logistics hub.

This strategic move culminated in an impressive automated pallet warehouse initially boasting 65,000 pallet locations, which was further expanded to accommodate over 100,000 pallet locations. The integration of cutting-edge technologies like the CycloneCarrier for light goods picking exemplifies the innovative approaches companies are taking to optimize their warehouse operations.

The importance of warehouse optimization stretches far beyond mere organization. It is about creating a synchronized environment where inventory management is precise, and goods movement is fluid.

Rueben Scriven of Interact Analysis underlines the anticipated surge in warehouse construction and how it will bolster demand for automation. With e-commerce sales soaring, the average new warehouse in the U.S. has grown significantly in size and height to meet this demand.

The trend is clear: investments in warehouse automation are on the rise, with expectations of double-digit revenue growth in the automation sector by 2025. These investments are not just in physical infrastructure but also in digital upskilling of the workforce. As hiring falls behind as a priority, companies are focusing on enhancing the skills of their existing employees, preparing them to work alongside advanced technologies. With over 150,000 warehouses worldwide, and that number projected to reach nearly 180,000 by 2025, the gap between large and small operations continues to widen. The larger players, often with global footprints, are investing more frequently in technologies to maintain a competitive edge. Efficient warehousing is therefore not just about physical space but also about integrating smart systems and training personnel to manage the complexities of modern logistics.

Best Practices for Warehouse Optimization

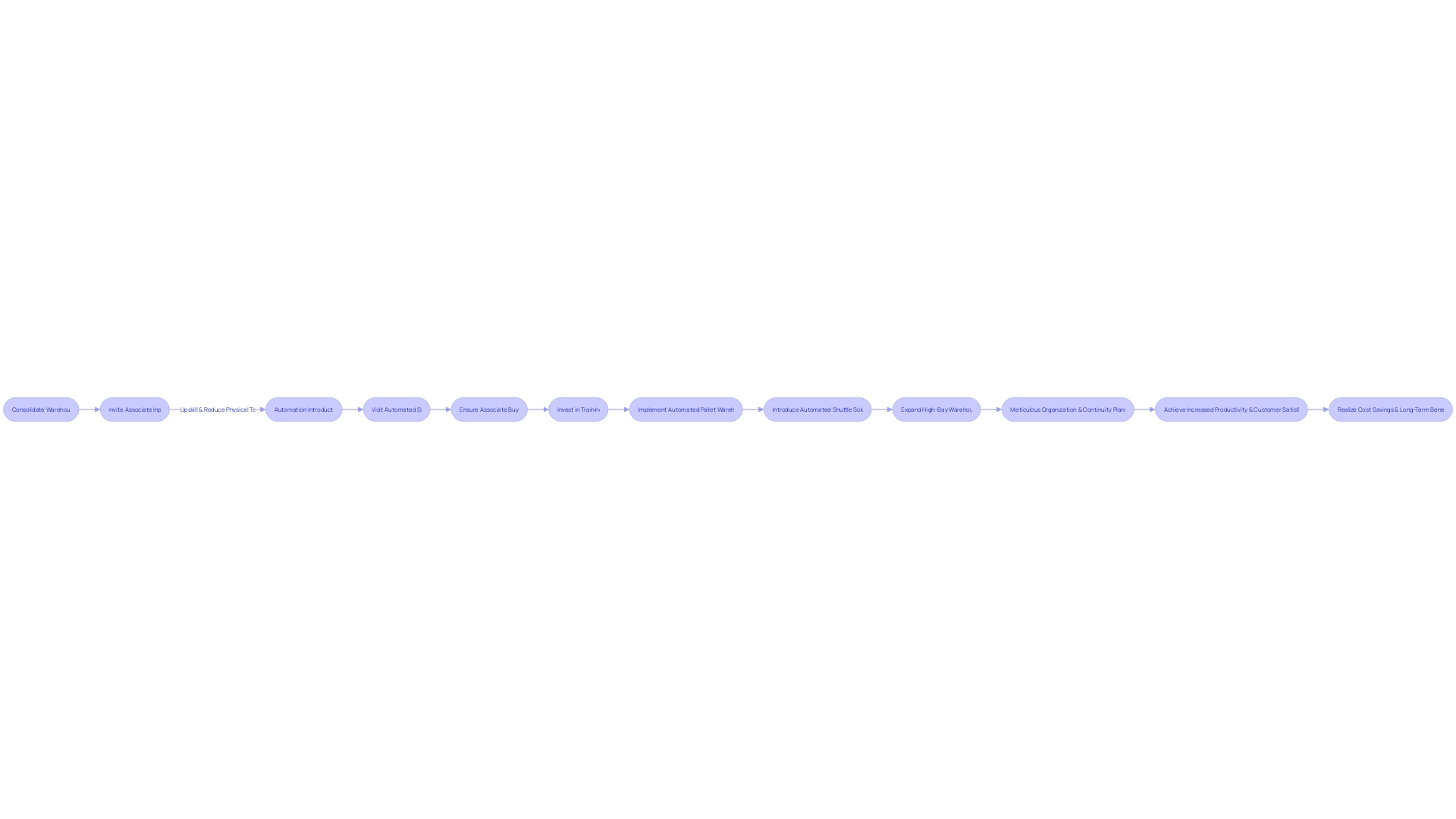

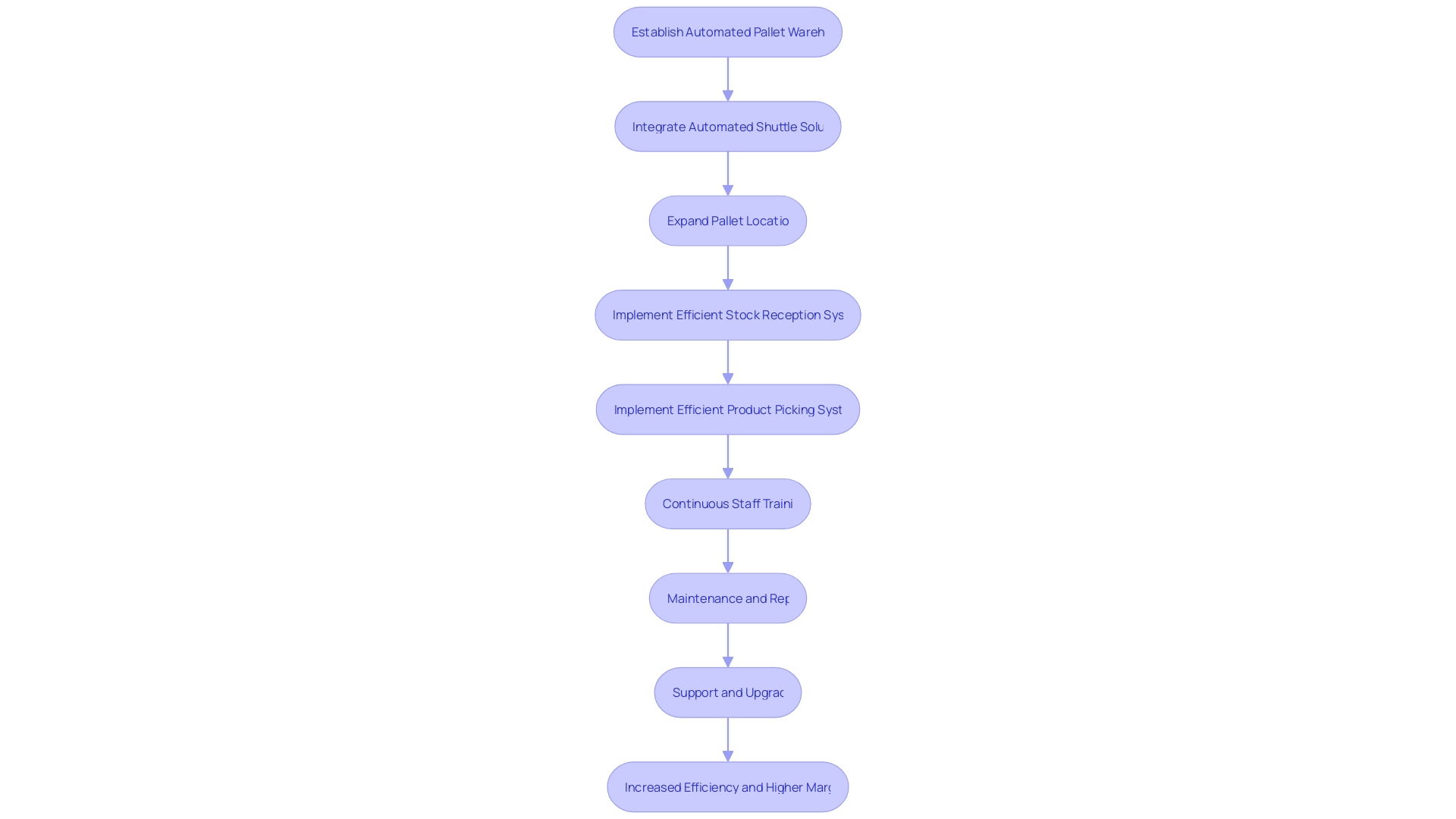

Warehouse consulting experts are at the forefront of driving efficiency and growth in the logistics sector. The key to a successful warehouse automation journey lies in strategic, phased implementation. For instance, a notable project involved consolidating six warehouses into a single, automated logistics center.

This project unfolded in three phases over six years, starting with an automated pallet warehouse equipped with 65,000 pallet locations and 11 Vectura pallet cranes. The second phase introduced an automated shuttle solution for light goods picking, and the expansion continued with the high-bay warehouse reaching over 100,000 pallet locations. To avoid bottlenecks, warehouses must maintain meticulous organization, starting from the receipt of goods to their logical storage.

This includes regular training to ensure all staff are familiar with policies and the use of efficient systems for stock acceptance and product picking. Furthermore, robust continuity planning is essential, requiring input from all business stakeholders including operational and engineering teams to ensure that automation aligns with the company's strategic goals and capabilities. Automation's benefits are clear, with many warehouses experiencing increased productivity, better customer demand fulfillment, and cost savings.

Yet, investment concerns persist amidst economic uncertainty. Despite apprehensions, automation remains a crucial step for warehouses to unlock future capacity, enhance agility, and drive efficiencies, potentially boosting profitability. As the market anticipates growth in warehouse construction and automation revenues in the coming years, companies are advised to consider the long-term benefits of strategic automation investment.

Data Analytics for Informed Decision Making

Harnessing the transformative power of data analytics is revolutionizing warehouse optimization. As businesses strive for competitiveness, it's the insights gleaned from data that illuminate the path forward.

Advanced analytics platforms, such as Dataiku, enable seamless integration of data from diverse sources, providing a centralized hub for exploratory analysis. This approach has proven pivotal for global enterprises, with one pharma giant dramatically streamlining their drug dosage inventory processes, thereby reducing human error and enhancing efficiency.

Efficient resource allocation is another facet where data analytics shines. For instance, through auto-scaling and multi-tenancy capabilities, businesses are witnessing a surge in infrastructure utilization.

This not only maximizes existing resources but also curtails overall expenses, as evidenced by reduced wastage reported by multiple teams leveraging platform enhancements. The realm of last-mile delivery has also been transformed by intelligent systems, such as the driver dispatch system.

By optimizing driver assignments, these systems ensure timely delivery while maintaining cost-effectiveness—crucial factors in satisfying customer expectations and maintaining operational excellence. The data warehouse has matured to accommodate a plethora of data types and workloads, including predictive analytics and IoT. According to Gigaom, modern data warehouses now support in-place querying, which negates the need to preload data, thus offering a more agile and powerful solution for today's complex data requirements. This evolution underscores the critical role data warehouses play in organizational data strategies, with a growing emphasis on real-time analytics and machine learning. In summary, data analytics is not just about collecting data; it's about transforming it into actionable insights. With the advent of new technologies and methodologies, such as generative AI and large language models, businesses are now equipped to make more informed, strategic decisions that propel them ahead in the competitive landscape.

Streamlining Warehouse Operations

To enhance warehouse operations, consider emulating the success of projects that have effectively consolidated multiple facilities into an automated logistics hub. For instance, a phased automation strategy can begin with establishing an automated pallet warehouse to provide tens of thousands of pallet locations managed by advanced cranes.

Following this, integrating automated shuttle solutions for picking operations can further streamline the workflow. Expansions can continue, potentially doubling the pallet locations and significantly boosting throughput.

In light of the surge in warehouse construction, expected to propel automation revenue growth into double digits by 2025, it's clear that investing in automated systems is a forward-thinking move. Statistics show that modern warehouses are not only expanding in footprint but also in height, catering to the increasing e-commerce demand.

For example, the average new warehouse in the U.S. now boasts an additional 108,665 square feet and 3.7 feet in height, particularly in markets close to major urban centers. Organizational efficiency is paramount, with the arrangement of stock playing a critical role.

Popular items should be easily accessible, with others placed logically to prevent operational chaos. Moreover, continuous staff training and efficient systems for stock reception and product picking are essential to maintain order. Experts highlight that a robust strategy for maintenance, repair, and support is crucial to minimize downtime in automated warehouses. With the right balance of technology and organization, warehouse operations can be transformed, leading to increased efficiency, reduced errors, and higher margins, as evidenced by leading industry players. By embracing flexibility and advanced planning, warehouse operators can prepare for future demands, ensuring agility in the face of evolving e-commerce trends and labor market challenges.

Implementing Effective Inventory Management Systems

Warehouse inventory management is the lifeblood of supply chain efficiency, central to ensuring products are available when and where they're needed. By deploying sophisticated inventory management systems, businesses can achieve real-time visibility and automation that revolutionizes stock handling. These systems play a pivotal role in averting stockouts and unnecessary overstock, refining order fulfillment, and streamlining cash flow.

For instance, Cycle Néron, once burdened by an outdated program leading to store closures for inventory counts, can now benefit from modern solutions that prevent such operational disruptions. Similarly, the Travel Charme Strandhotel, with its high guest turnover, necessitates an efficient system to manage the constant flow of inventory required for a seamless hospitality experience. In the current retail landscape, as exemplified by Crew Clothing's drive for a unified platform, the integration of inventory management systems is not just a luxury but a strategic imperative.

These systems are instrumental in forecasting demand and recognizing less active or outdated items, thereby optimizing reorder points and quantities. Moreover, the Kanban system encourages collaboration and continuous improvement, ensuring the efficient movement of goods through various warehouse stages. The adoption of technology also brings about a significant shift in workforce dynamics.

With only 8% of supply chain executives prioritizing new hiring, the focus has turned to digital upskilling of existing staff, with 18% naming it a top priority. This investment in technology is underscored by findings from PwC's 2023 Digital Trends in Supply Chain Survey, indicating a strong inclination towards embedding new technologies into business models, with 59% of business executives planning investments in the coming years. Effective inventory management is not just about keeping stock; it's about optimizing every facet of warehouse operations to meet the evolving demands of the market, ensuring resilience, and driving growth.

Conclusion

In conclusion, warehouse optimization is crucial for enhancing business operations and driving growth in the logistics sector. By strategically managing challenges and integrating technology, warehouses can streamline inventory control and fortify their supply chain.

Automation plays a pivotal role in reshaping warehouse operations, with investments on the rise to meet increasing e-commerce demand. Successful warehouse optimization requires phased implementation, meticulous organization, regular training, and efficient systems.

Continuity planning ensures that automation aligns with company goals and capabilities. Data analytics revolutionizes warehouse operations by providing actionable insights from diverse data sources.

Streamlining warehouse operations involves consolidating facilities into automated logistics hubs. Investing in automated systems is essential for meeting future capacity needs and enhancing agility.

Organizational efficiency, stock arrangement, staff training, and robust maintenance strategies are key to transforming warehouse operations. Effective inventory management is central to supply chain efficiency and requires sophisticated systems for real-time visibility and automation. Digital upskilling of existing staff is necessary to adapt to technological advancements. In summary, optimizing warehouse operations through strategic management, technology integration, data analytics utilization, streamlined processes, and effective inventory management is crucial for navigating the complexities of modern logistics successfully. By embracing these practices and investing in automation and digital upskilling, warehouses can enhance efficiency, reduce errors, maintain agility in an evolving market landscape while driving growth and profitability.