Introduction

Embarking on a digital transformation journey, industrial operations face various challenges that hinder efficiency and productivity. In order to overcome these obstacles, companies must identify and address specific problems through a problem-solving mindset and a commitment to lean, data-centric operations.

This article explores the importance of data quality, the market shift towards customization and competitive pricing, and the need for streamlined workflows. Additionally, it highlights how leveraging IIoT consulting can drive efficiency and growth in industrial operations by integrating disparate data sources, optimizing overall equipment effectiveness (OEE), and enabling predictive maintenance. By embracing these solutions, businesses can gain data-driven insights and improve their operations, ultimately enhancing productivity, reducing costs, and remaining competitive in the industry.

Problem: Challenges in Industrial Operations

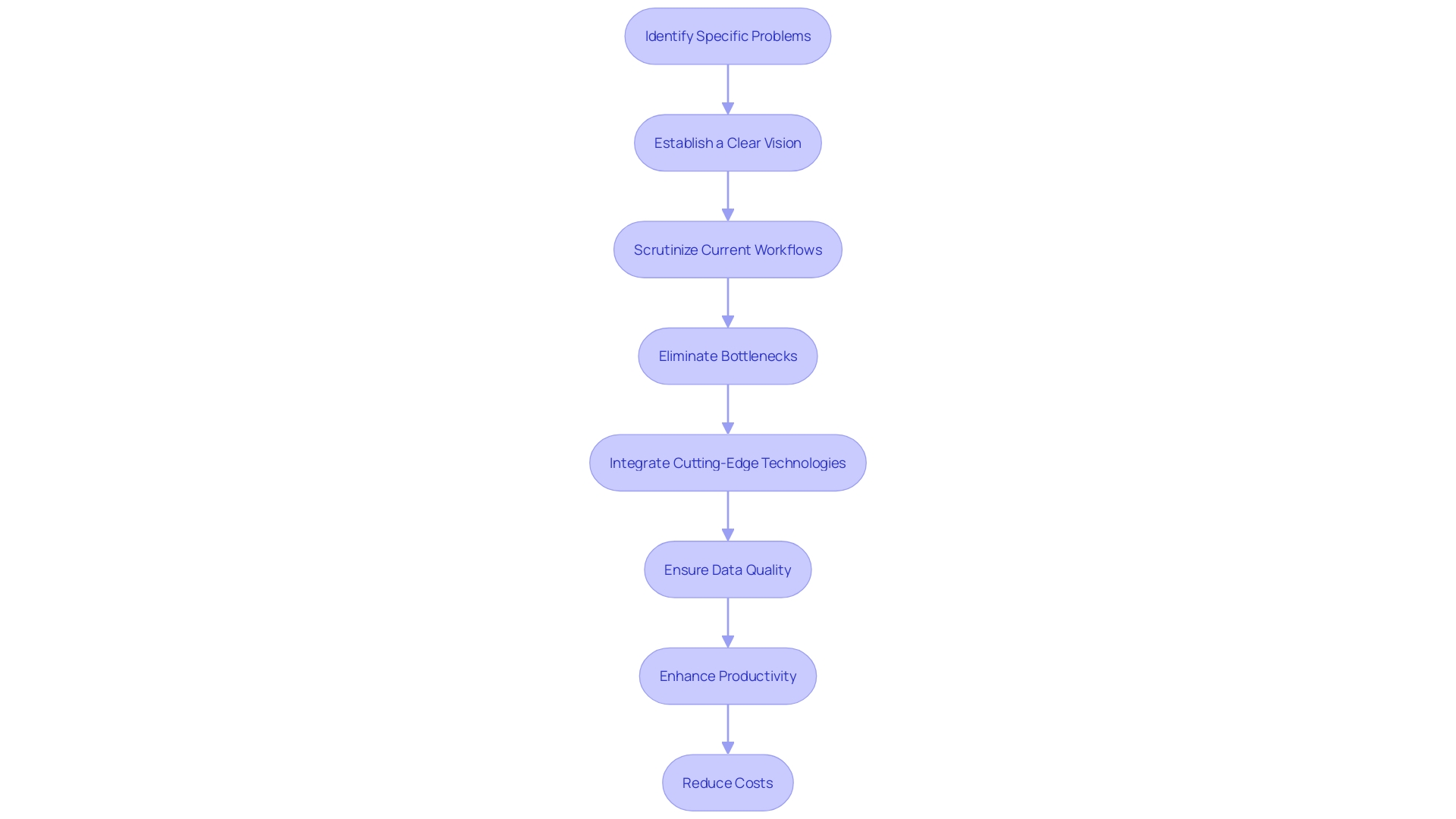

Embarking on a digital transformation journey, industrial operations must pivot from legacy systems and manual inefficiencies towards streamlined, data-driven processes. A crucial first step is pinpointing the specific problems to solve, informed by a clear vision and purpose for transformation.

To lay the groundwork for effective change, companies should scrutinize their current workflows to identify and eliminate bottlenecks, embracing a lean methodology that will serve as a robust foundation for integrating cutting-edge technologies. As Jane Arnold from Aperio highlights, ensuring data quality is non-negotiable.

With the industrial sector inundated with data, the ability to sift through and rectify data inaccuracies is vital for maintaining operational efficiency and reliability. Real-world implications of data anomalies are tangible: an industrial gas company's configuration errors and a year-long flatline of a critical environmental tag underscore the importance of continuous data monitoring. The market shift, driven by consumer demands for customization, competitive pricing, and optimal delivery, further pressures manufacturers to overhaul their approach. Ultimately, by addressing these challenges with a strategic, problem-solving mindset and a commitment to lean, data-centric operations, industrial companies can enhance productivity, reduce costs, and remain competitive.

Solution: Leveraging IIoT Consulting for Efficiency and Growth

In the dynamic world of industrial operations, the advent of Industry 4.0 has been a game-changer, paving the way for the Industrial Internet of Things (IIoT) to transform key performance indicators. IIoT consulting firms are at the forefront of this revolution, harnessing IoT networks, cognitive computing, robotics, and automation to propel businesses into a new era of efficiency and innovation.

With a deep understanding of technology architecture, including PLCs and tethered connectivity, these experts craft bespoke solutions that not only integrate disparate data sources but also optimize Overall Equipment Effectiveness (OEE) and drive cost savings. The value of IIoT consulting is underscored by the staggering amount of data produced by industrial equipment, like a wind turbine generating 1 terabyte of data weekly, which is meticulously analyzed to monitor and maintain efficiency.

These insights are critical for condition-based monitoring (CBM), a practice that reduces unplanned downtime, which accounts for 64% of such occurrences due to equipment failures. By leveraging IIoT, businesses gain a comprehensive view of their operations, allowing for predictive maintenance and quality control, such as in paper manufacturing where IoT technology tracks roll press conditions to ensure product quality. This integration of modern industry 4.0 tech stack elements facilitates not just data collection but a transformative analysis, enabling smarter, data-driven decisions for safer, more productive industries.

Results: Data-Driven Insights and Improved Operations

Industrial Internet of Things (IIoT) consulting services are a cornerstone in the digital transformation of industries. They play a critical role in ushering in the era of Industry 4.0, defined by IoT Analytics as the integration of modern tech stack elements or supporting technologies.

These technologies are instrumental in achieving higher operational equipment effectiveness (OEE), reducing costs, and improving key performance indicators (KPIs) in manufacturing and related sectors. IIoT's focus on improving efficiency, productivity, and safety is transforming industrial operations.

For instance, in the renewable energy sector, a wind turbine generates approximately 1 terabyte of data weekly, which is crucial for condition-based monitoring (CBM). This data, ranging from vibration frequencies to temperature variations, is used to assess the turbine's health.

Similarly, in paper manufacturing, IIoT enhances the monitoring of roll presses, indirectly influencing product quality. IIoT's ability to offer real-time operational visibility and control remotely has led to a 64% reduction in unplanned downtime caused by equipment failures. By enabling the aggregation of data from multiple sources, IIoT provides a comprehensive operational overview, ensuring equipment health and fostering a proactive maintenance culture. Moreover, the data collected serves as a foundation for training machine learning models, further enhancing predictive maintenance capabilities. This holistic approach to industrial operations not only minimizes waste and optimizes resource allocation but also significantly elevates customer satisfaction by improving product quality.

Conclusion

In conclusion, industrial operations face various challenges in their digital transformation journey. To overcome these obstacles, companies must adopt a problem-solving mindset and commit to lean, data-centric operations. It is crucial to prioritize data quality as it is essential for maintaining operational efficiency and reliability.

The market shift towards customization, competitive pricing, and optimal delivery further emphasizes the need for industrial companies to overhaul their approach. By addressing these challenges strategically, businesses can enhance productivity, reduce costs, and remain competitive in the industry. Leveraging IIoT consulting services is a solution that can drive efficiency and growth in industrial operations.

These experts harness IoT networks, cognitive computing, robotics, and automation to integrate disparate data sources and optimize Overall Equipment Effectiveness (OEE). The insights gained from the analysis of vast amounts of data enable condition-based monitoring (CBM) and predictive maintenance, ultimately reducing unplanned downtime and improving product quality. The integration of modern tech stack elements facilitated by IIoT consulting services provides comprehensive operational visibility and control remotely.

This leads to higher OEE, reduced costs, improved key performance indicators (KPIs), and enhanced customer satisfaction. By embracing these solutions and leveraging IIoT consulting services, businesses can gain data-driven insights and improve their operations. Ultimately, this will enhance productivity, reduce costs, and allow them to remain competitive in the industry.

Ready to optimize your industrial operations? Contact our team of experts today!