Introduction

The integration of Industrial Internet of Things (IIoT) technology into the e-commerce sector has revolutionized business operations and customer experiences. By connecting physical devices, buildings, and vehicles with sensors and network connectivity, businesses can gather real-time data and gain valuable insights into supply chain management and customer behavior. This data-driven approach enables businesses to make informed decisions, improve operational efficiency, and enhance customer satisfaction. In this article, we will explore the impact of IIoT on e-commerce, discuss case studies of successful implementations, and provide strategies for adopting IIoT in e-commerce businesses.

Industrial IoT has the potential to transform various aspects of e-commerce, from supply chain management to customer service. By leveraging IoT devices and sensors, businesses can collect data from different sources and analyze it in real-time to optimize their operations. We will examine real-world examples of how IIoT has been implemented in manufacturing processes and how it has led to improved efficiency, reduced downtime, and cost savings. Additionally, we will discuss the best practices for successful adoption of IIoT in e-commerce, including selecting the right IoT devices, ensuring data security, and investing in analytics tools. By understanding the transformative power of IIoT in e-commerce and implementing it strategically, businesses can gain a competitive edge in the digital landscape.

1. Understanding the Role of Industrial IoT in E-commerce

The integration of the Industrial Internet of Things (IIoT) into the e-commerce sector has brought about a significant transformation. This revolution is achieved through a complex network of interconnected physical devices, vehicles, buildings, and other items equipped with sensors, software, and network connectivity. These components work together to gather and exchange data, providing real-time insights into various business areas, including supply chain management and customer behavior. With the aid of this data-driven approach, businesses can make more informed decisions, improve operational efficiency, and ultimately enhance customer satisfaction.

The importance and benefits of IIoT are extensively discussed in various white papers. In the white paper "Achieving digital transformations with IoT and big data", the focus is on how IoT and big data can be implemented in enterprise organizations. The paper emphasizes the critical role of harnessing the vast amounts of data generated from various sources effectively.

Another white paper, "Implementing IoT in modern supply chain", explores the impact of IoT on modern supply chains. It underscores the interconnectedness of devices and the sharing of data to improve user experiences. This interconnectedness is crucial in e-commerce businesses, where real-time data can significantly enhance supply chain management.

The white paper "Implementing IoT in your manufacturing business" delves into the implementation of IoT in the manufacturing industry. It discusses how interconnected devices and sensors can transform the physical world into an information system, providing a wealth of data for businesses to analyze and utilize.

In the white paper titled "IoT: The next phase in the evolution of the internet", the evolution of the internet is discussed. The paper emphasizes how the internet has transformed into a platform for devices to communicate electronically and share information. This transformation is at the heart of IIoT, which leverages this connectivity to enhance various aspects of e-commerce businesses.

The implementation of IIoT in e-commerce provides numerous benefits, including improving operational efficiency, enhancing supply chain management, and providing a better customer experience. IIoT enables real-time monitoring and data collection, allowing businesses to track inventory levels, optimize warehouse operations, and automate order fulfillment processes. It enables predictive maintenance of equipment, reducing downtime and ensuring uninterrupted operations. Furthermore, IIoT allows personalized marketing and targeted advertising based on customer behavior and preferences, leading to increased customer engagement and conversion rates.

By utilizing IIoT devices, such as sensors and smart devices, businesses can collect data from various sources, such as inventory management systems, supply chain processes, and customer behavior. This data can then be analyzed in real-time to gain valuable insights into trends, patterns, and potential issues. This proactive decision-making approach allows businesses to identify bottlenecks in the supply chain, monitor inventory levels, predict customer demand, and optimize their operations.

Industrial IoT has the potential to revolutionize supply chain management in e-commerce, enhancing operational efficiency and customer satisfaction. By leveraging IoT devices and sensors, businesses can gain real-time visibility into their inventory, logistics, and delivery processes. This enables them to track products throughout the entire supply chain, from production to delivery, and make data-driven decisions to optimize efficiency and reduce costs.

To enhance customer satisfaction with IIoT in e-commerce, it is crucial for software developers, designers, and engineers to work together to craft innovative solutions. This collaborative approach can speed up development, test hypotheses, and align the product with the market. Additionally, full outsourcing services are available for quick proof of concept, initial project research, bug fixes, and market alignment.

To optimize e-commerce operations, IIoT solutions can be implemented. These solutions leverage IoT technology to enable real-time monitoring and control of various aspects of the e-commerce supply chain, such as inventory management, logistics, and order fulfillment. By integrating IoT devices and sensors with the e-commerce infrastructure, businesses can gain valuable insights into their operations, identify bottlenecks, and automate processes for increased efficiency and cost-effectiveness.

When integrating IIoT in e-commerce, it is important to follow some best practices to ensure a successful implementation. These best practices include defining clear objectives, choosing the right IoT devices, ensuring data security, integrating with existing systems, optimizing data analytics, continuous monitoring and maintenance, and planning for scalability.

For e-commerce businesses looking for IIoT platforms, it is important to find a solution that can efficiently integrate and manage IoT devices and data within their operations. By leveraging IoT technology, businesses can enhance their supply chain management, improve inventory tracking, and optimize their overall operations. It is crucial for e-commerce businesses to select a reliable and scalable IIoT platform that can meet their specific needs and provide seamless integration with their existing systems.

The transformative power of IIoT in the realm of e-commerce is undeniable. By using the data generated through this network of interconnected devices, businesses can make more informed decisions, optimize their operations, and ultimately enhance customer satisfaction.

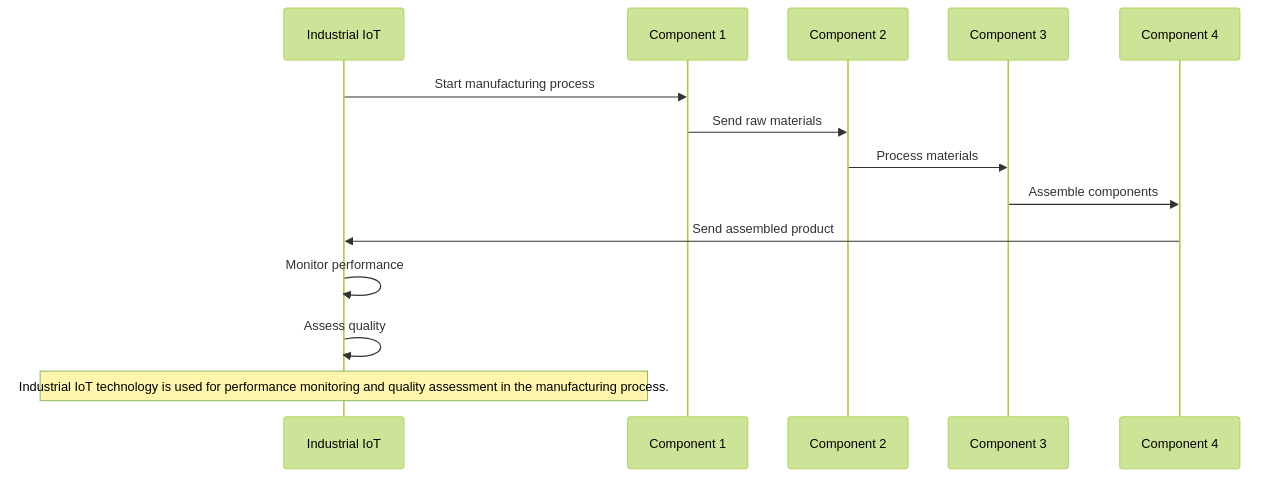

2. Case Study: Implementing Industrial IoT for Performance Monitoring in Manufacturing

Industrial Internet of Things (IIoT) technology is revolutionizing sectors far and wide, and the manufacturing industry is no exception.

One such instance of this transformative power is its application in the manufacturing process of piston rods, as demonstrated by EdgeX Foundry, a platform that enables automation and monitoring across various industries.

The manufacturing of piston rods, used in diverse applications from construction to mining, involves a sequential process. Each stage, whether it's induction hardening, friction welding, threading, or polishing, necessitates a quality checkpoint for detecting potential defects. Traditionally, the final station of the manufacturing process carries out a surface-level quality inspection, which is heavily reliant on manual inspection. While effective, this method can be time-consuming, costly, and dependent on human judgment.

To counter these challenges, an innovative solution was proposed: an automated surface quality inspection system rooted in artificial intelligence and machine learning. This system, powered by EdgeX Foundry's software stack, employs image analytics to enable quality assessment. It involves edge gateway hardware, an industrial-grade camera, and an edge software stack, bolstered by a deep machine learning model and Intel's OpenVINO toolkit for image analysis and inference. The solution also features EdgeX Device Service Layer enhancements for facilitating southbound connectivity and automated decision-making.

With this system, real-time visibility of key performance indicators through dashboards becomes possible, leading to efficient monitoring of plant performance. Furthermore, the system links to business applications hosted on the cloud, offering actionable insights and visual aids. This not only curtails the cost of inspection but also ensures consistent performance, centralized management, and real-time visibility of plant operations. Continuous retraining of the deep learning models guarantees the accuracy and effectiveness of the automated inspections, reducing reliance on human judgment and making the system available round the clock.

Another similar instance is that of Hirotec, a global auto parts manufacturer, which embarked on an IoT initiative to optimize its manufacturing processes and enhance efficiency. Despite facing challenges such as data integration, connectivity, and security during the implementation of its IoT solution, Hirotec managed to overcome these obstacles by partnering with an IoT platform provider. This led to improved production line efficiency, reduced downtime, and enhanced overall operational performance. The company also utilized real-time data analytics to gain insights into its manufacturing processes and make data-driven decisions.

These examples showcase the transformative power of IIoT in the manufacturing sector, illustrating how it can streamline operations, improve efficiency, and ultimately, drive growth in e-commerce. With the help of software developers, designers, and engineers, businesses can leverage innovative solutions for performance monitoring in manufacturing using industrial IoT. These professionals can provide customized solutions that cater to specific needs and questions. They offer services such as testing market fit, launching minimum viable products (MVPs), testing hypotheses, and providing bug fixes. By integrating their services with existing teams, businesses can speed up development and ensure market success. This takes the potential of IIoT in revolutionizing manufacturing to new heights.

3. Strategies for Successful Adoption of Industrial IoT in E-commerce Businesses

In the e-commerce landscape, the strategic integration of Industrial IoT can usher in noteworthy improvements across diverse business dimensions, from inventory management to customer service. Hirotec, a global automotive supplier, serves as a testament to this, having successfully utilized IoT to enhance its manufacturing processes and customer satisfaction.

The initial step towards a thriving Industrial IoT incorporation is identifying potential areas for value creation. This is a task that Hirotec undertook, acknowledging the challenges such as data security, connectivity, and interoperability. They then forged an all-encompassing IoT strategy to tackle these issues. This plan underscored collaboration, standardization, and innovation, all of which were pivotal in surmounting the hurdles.

The selection of the right IoT devices and sensors compatible with specific e-commerce operations is paramount. The chosen devices should be capable of gathering pertinent data and offering real-time insights into various business facets, such as inventory management, supply chain optimization, and customer behavior analysis.

A sound connectivity infrastructure to support the IoT devices is another critical consideration. This encompasses robust network capabilities, such as reliable Wi-Fi or cellular connectivity, and secure data transmission protocols to safeguard sensitive information.

Moreover, investment in capable analytics tools and platforms that can effectively process and interpret the collected IoT data is crucial. These tools can furnish valuable insights, aiding businesses in making data-driven decisions, optimizing their operations, and enhancing overall efficiency.

In terms of cybersecurity, it is essential to prioritize measures to protect IoT systems from potential threats. This includes implementing strong authentication mechanisms, encryption protocols, and regular security audits to identify and address vulnerabilities.

Coca Cola İçecek (CCI), a key bottler in the Coca Cola system based in Istanbul, Turkey, exemplified the importance of investing in the right technology infrastructure in the Industrial IoT implementation journey. They leveraged Amazon Web Services (AWS) to build a digital twin of its 26 bottling plants. The objective was to automate the shop floor operations and acquire a comprehensive view of its manufacturing processes. AWS IoT Sitewise was employed to gather and process industrial data, constructing digital models of CCI's assets and processes. This innovative approach empowered CCI operators to monitor processes almost in real-time and make data-driven decisions, demonstrating the potency of the right technology infrastructure.

Ensuring that the workforce is equipped with the necessary skills to manage the new technology is fundamental. Hirotec exemplified this by investing in training and development programs for its employees, ensuring they possess the required expertise to work with IoT technology. This initiative has led to improved operational efficiency and cost savings within the company's manufacturing plants.

To train employees for the adoption of industrial IoT in e-commerce, businesses should provide specialized training programs focusing on IoT technologies and their application in the e-commerce industry. These programs should cover topics such as IoT architecture, data analytics, cybersecurity, and integration with existing e-commerce systems. Hands-on workshops and case studies can provide employees with practical experience in implementing IoT solutions in an e-commerce environment.

Finally, businesses should continuously monitor and evaluate the performance of their IoT implementation. This involves analyzing key performance indicators (KPIs) and metrics to ensure that the IoT systems are delivering the expected benefits and meeting the specific needs of the e-commerce business.

In sum, the strategic incorporation of Industrial IoT in e-commerce businesses can lead to substantial improvements in various areas, provided that the potential areas of value-addition are identified, the right technology infrastructure is in place, and the workforce is adequately skilled to handle the new technology. The experiences of Hirotec and CCI serve as excellent examples of the profound impact of Industrial IoT when strategically implemented.

4. Best Practices: Minimizing Uncertainty and Maximizing Scalability with Industrial IoT

As industrial IoT adoption takes center stage, it is paramount to focus on mitigating uncertainties and enhancing scalability. A phased approach, starting with a pilot project and gradually transitioning to a full-scale implementation, can be an effective strategy. It's also vital to set definitive objectives and success metrics, and continually evaluate and adjust the strategy as needed.

In today's digital age, the increased connectivity and data accumulation that comes with Industrial IoT expose businesses to a myriad of new risks. This makes data security and privacy a top priority. Secure connections between Operational Technology (OT) and Information Technology (IT) systems have emerged as a key focus area in industries such as manufacturing. The implementation of next-generation firewalls and trust boundaries to limit network traffic is a recommended practice to secure all layers of the industrial environment.

Further, improving asset traceability and observability is crucial. This can be accomplished by maintaining an inventory of network assets and automating resource management. This not only assists in identifying rogue assets but also contributes to reducing the attack surface by managing devices and gateways, and by disabling or removing unused services and protocols.

The creation of secure network connections to the cloud is vital, and tools such as AWS Direct Connect and AWS VPN can be utilized for this purpose. To ensure the security of operational data, it is advised to encrypt data both in transit and at rest, and to implement the principle of least privilege, granting access to data only to those resources that require it.

Continuous monitoring of IoT devices and network traffic is another best practice, with AWS services like AWS IoT Device Defender and Amazon GuardDuty being viable options for this purpose. Ultimately, securing your Industrial IoT implementation is not just about protecting data but also about maintaining the performance and stability of your operations.

Industrial IoT adoption brings the potential for increased efficiency and productivity, but it also introduces new security risks that must be effectively managed. By adhering to these best practices, businesses can ensure that their Industrial IoT implementations are secure, scalable, and successful.

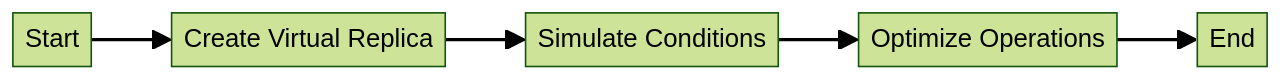

5. Case Study: Utilizing Operational Digital Twin Technology for Analytical Instrumentation

The utilization of Industrial IoT in e-commerce has seen a significant surge, particularly with the advent of Operational Digital Twin technology.

This advanced technology forms a virtual representation of a physical asset, serving a variety of purposes, such as performance monitoring and predictive maintenance. Notably, this technology was used by a renowned e-commerce company for analytical instrumentation optimization.

By creating a virtual mirror image of their physical instruments, the company was able to simulate various conditions, ultimately leading to operational optimization and a significant reduction in downtime. However, the application of this technology is not limited to e-commerce; it has extensive applications across various sectors.

For instance, Tata Consultancy Services (TCS), a global technology company operating in 131 countries, has been at the forefront of innovation for over five decades. They provide solutions for a wide array of industries, including banking, consumer goods, healthcare, and more. Among their diverse range of products and platforms is TCS Twinx™, a digital twin product.

Their remarkable achievement in this domain includes the implementation of a digital twin for Tata Chemicals' carbonation towers and boilers. This resulted in annual cost savings of $600,000, showcasing the potential of this technology in optimizing operations and reducing costs.

Another case study that highlights the effectiveness of this technology is Coca-Cola İçecek's (CCI) use of Amazon Web Services (AWS) to construct a digital twin of their 26 bottling plants. The aim of this initiative was to automate the shop floor while also providing a comprehensive view of the manufacturing process.

CCI utilized AWS IoT Sitewise, a service that collects and organizes data from industrial equipment, to create a virtual replica of their clean-in-place (CIP) process, a sanitation process crucial to the food and beverage industry. By leveraging AWS services, CCI enhanced communication between operators and IoT devices, leading to better asset optimization and sustainability.

The digital twin solution enabled CCI to identify over 30 areas of improvement, resulting in annual savings of 20% on electricity and 9% on water. These significant savings emphasize the potential of digital twin technology in optimizing resources and reducing environmental impact.

CCI plans to extend the application of the digital twin solution to all 26 of its plants, further underscoring the scalability and adaptability of this technology. They also plan to continue developing machine learning models on AWS to drive intelligence on the shop floor, indicating the vast potential of Industrial IoT in transforming operations across industries.

These case studies aptly demonstrate the transformative potential of Operational Digital Twin technology in various industries, from e-commerce to manufacturing. By creating a virtual replica of physical assets, businesses can optimize their operations, reduce downtime, and achieve significant cost savings. The future of Industrial IoT seems promising with the advent of such innovative applications.

Operational digital twin technology can offer several benefits in various use cases within the e-commerce industry. It can aid in optimizing supply chain management by creating virtual replicas of physical assets and monitoring their performance in real-time. This can lead to improved inventory management, enhanced order fulfillment, and efficient logistics planning.

Moreover, operational digital twins can be employed for predictive maintenance, enabling e-commerce companies to identify potential equipment failures before they occur, thereby minimizing downtime and ensuring uninterrupted operations. Additionally, digital twins can be utilized for personalized marketing and customer experience enhancement by analyzing customer behavior data and creating virtual models of individual customers. This can lead to targeted advertising, personalized recommendations, and tailored shopping experiences, ultimately resulting in increased customer satisfaction and loyalty.

Operational digital twin technology also allows software developers, designers, and engineers to work in harmony and craft innovative solutions specific to the needs of the e-commerce industry. With this technology, businesses can schedule consultations with experts to gain insights and guidance. This technology also facilitates access to top-tier talent, enabling businesses to learn and implement the most cost-effective and flexible solutions. By integrating operational digital twin technology into existing teams, businesses can expedite development, test hypotheses, and ensure market fit.

Overall, it empowers businesses in the e-commerce industry to launch minimum viable products (MVPs), test market fit, and drive innovation. Furthermore, operational digital twin technology provides full outsourcing capabilities, including bug fixes, market alignment, and initial project research.

6. Asset Performance Management: A Key Component of Industrial IoT Consulting

In the realm of e-commerce, the importance of Asset Performance Management (APM) is paramount, with Industrial IoT playing a crucial role. APM harnesses the power of data analytics to boost the reliability and availability of physical assets. This is especially relevant to the e-commerce sector, where assets such as warehouse machinery and delivery vehicles need constant monitoring. With Industrial IoT technology, businesses can collect real-time data on these assets, analyze the data to identify potential issues and implement preventive measures to avoid equipment failure and optimize performance.

Consider the case of HKTVMall, Hong Kong's largest 24-hour online shopping mall, which experienced a tenfold increase in traffic during the COVID-19 pandemic. Their previous SAP Hybris e-commerce platform could not handle the surge in online shopping. To address this issue, they utilized AppDynamics, an application performance monitoring solution. This provided HKTVMall with real-time visibility and system information, ensuring smooth operation of vital e-commerce processes. Consequently, server performance improved, potential performance issues were identified and resolved, providing HKTVMall with the assurance it needed.

Another e-commerce website, Privalia, transitioned to a microservices-based architecture and employed AppDynamics to monitor their new cloud-based application platform. AppDynamics allowed Privalia to manage dependencies between microservices and visualize the transaction flow between applications. This resulted in a 68% reduction in production errors and a 325% increase in platform capacity to serve simultaneous users.

The instances above highlight the vital role of APM in maintaining e-commerce operations. By proactively identifying and resolving potential performance issues, businesses can ensure the smooth operation of their platforms even during periods of high customer activity. This not only improves server performance but also provides peace of mind, allowing businesses to concentrate on driving growth and delivering a seamless, high-quality shopping experience.

Data analytics can be a powerful tool for optimizing performance and making informed decisions in APM. By analyzing data, businesses can gain valuable insights into the health and performance of their assets, identify patterns and trends, and make data-driven decisions to improve efficiency and reduce costs. Implementing advanced analytics techniques, real-time monitoring systems and visualization tools can help businesses uncover hidden insights, track the performance of assets continuously, and present the analyzed data in a clear and understandable format.

Industrial IoT technology provides several benefits for APM. By leveraging IoT sensors, devices, and connectivity, organizations can gain real-time insights into the performance of their assets, enabling proactive maintenance and reducing downtime. IoT technology also allows for remote monitoring and predictive analytics, optimizing asset utilization and improving overall operational efficiency.

There are various tools available for monitoring and analyzing asset performance in e-commerce, such as Google Analytics, New Relic, Pingdom, and Dynatrace. These tools provide comprehensive monitoring capabilities and powerful analytics features to help businesses make data-driven decisions and improve the performance of their e-commerce assets.

To optimize performance and prevent equipment failure in e-commerce, several steps can be taken, including regular monitoring and analysis of the e-commerce platform, implementing caching mechanisms, having a reliable hosting infrastructure, conducting regular maintenance and updates, and conducting regular performance testing and load testing.

In conclusion, to improve asset reliability and availability in e-commerce, it is important to take proactive measures, such as regular maintenance and inspections of the assets, implementing performance monitoring systems, and investing in redundancy and backup solutions. By continuously monitoring the performance of assets and addressing any issues promptly, e-commerce businesses can minimize downtime and ensure a smooth user experience for their customers. Additionally, having backup systems in place can help mitigate the impact of any potential failures and ensure continuous operations.

Conclusion

The integration of Industrial Internet of Things (IIoT) technology into the e-commerce sector has revolutionized business operations and customer experiences. By connecting physical devices, buildings, and vehicles with sensors and network connectivity, businesses can gather real-time data and gain valuable insights into supply chain management and customer behavior. This data-driven approach enables businesses to make informed decisions, improve operational efficiency, and enhance customer satisfaction.

Industrial IoT has the potential to transform various aspects of e-commerce, from supply chain management to customer service. By leveraging IoT devices and sensors, businesses can collect data from different sources and analyze it in real-time to optimize their operations. Real-world examples of successful IIoT implementations in manufacturing processes have shown improved efficiency, reduced downtime, and cost savings. To successfully adopt IIoT in e-commerce, businesses must select the right IoT devices, ensure data security, invest in analytics tools, and plan for scalability. By understanding the transformative power of IIoT in e-commerce and implementing it strategically, businesses can gain a competitive edge in the digital landscape.