Introduction

The transition from reactive to predictive maintenance by the e-commerce company marked a significant shift towards bolstering their operational efficiency. Faced with frequent equipment breakdowns and unexpected downtimes, the company realized the need for strategic change. This article explores the implementation of predictive maintenance applications in the e-commerce sector, showcasing the profound impact of digital transformation.

By deploying IoT-based predictive maintenance systems, integrating real-time data, and leveraging advanced machine learning algorithms, businesses can preempt machine failures and optimize maintenance operations. The benefits of predictive maintenance include cost savings, enhanced operational workflow, improved customer satisfaction, and increased productivity. With the integration of machine intelligence and data analysis, predictive maintenance serves as a beacon for businesses looking to leverage advanced digital technologies for long-term success in the evolving e-commerce landscape.

Background

The transition from reactive to predictive maintenance by the e-commerce company marked a significant shift towards bolstering their operational efficiency. Distressed by frequent equipment breakdowns and unexpected downtimes that were diminishing both productivity and profitability, it was clear a strategic change was imperative. The leap to predictive maintenance hinged on an intricate choreography of data patterns and a commitment to iterative learning, an approach empowering them to preempt potential malfunctions.

Machine learning, at the heart of this transformation, leveraged vast datasets to discern intricate relationships and implicit rules, heightening the accuracy of predictions and preemptive actions. Experts point out that machine learning surpasses conventional programming where the coder commands a computer's every move; instead, it educates the computer to recognize data trends over time. This methodology, particularly potent with time series data, is transformative across an array of applications, inclusive of predictive maintenance which, in turn, is pivotal for modern e-commerce operations burdened with expansive and intricate infrastructures.

Interviews with industry specialists revealed a consensus that adapting to changing consumer expectations around customization, competitive pricing, and swift delivery is non-negotiable, necessitating the harnessing of advanced digital technologies like AI, digital twins, and machine intelligence. Utilizing such tools not only drives productivity but also caters to the evolving market demands. For instance, deploying InfluxDB facilitates the scrutiny and storage of data from network-connected devices, which is integral to predictive maintenance and its myriad advantages for business vitality and competitive edge.

Implementing Predictive Maintenance Applications

In an era driven by consumer demands for bespoke products, competitive costs, and swift delivery, our e-commerce sector must innovate to stay ahead. Key to this strategy has been the rollout of IoT-based predictive maintenance applications, a move that stands as a testament to the profound impact of digital transformation in recent years.

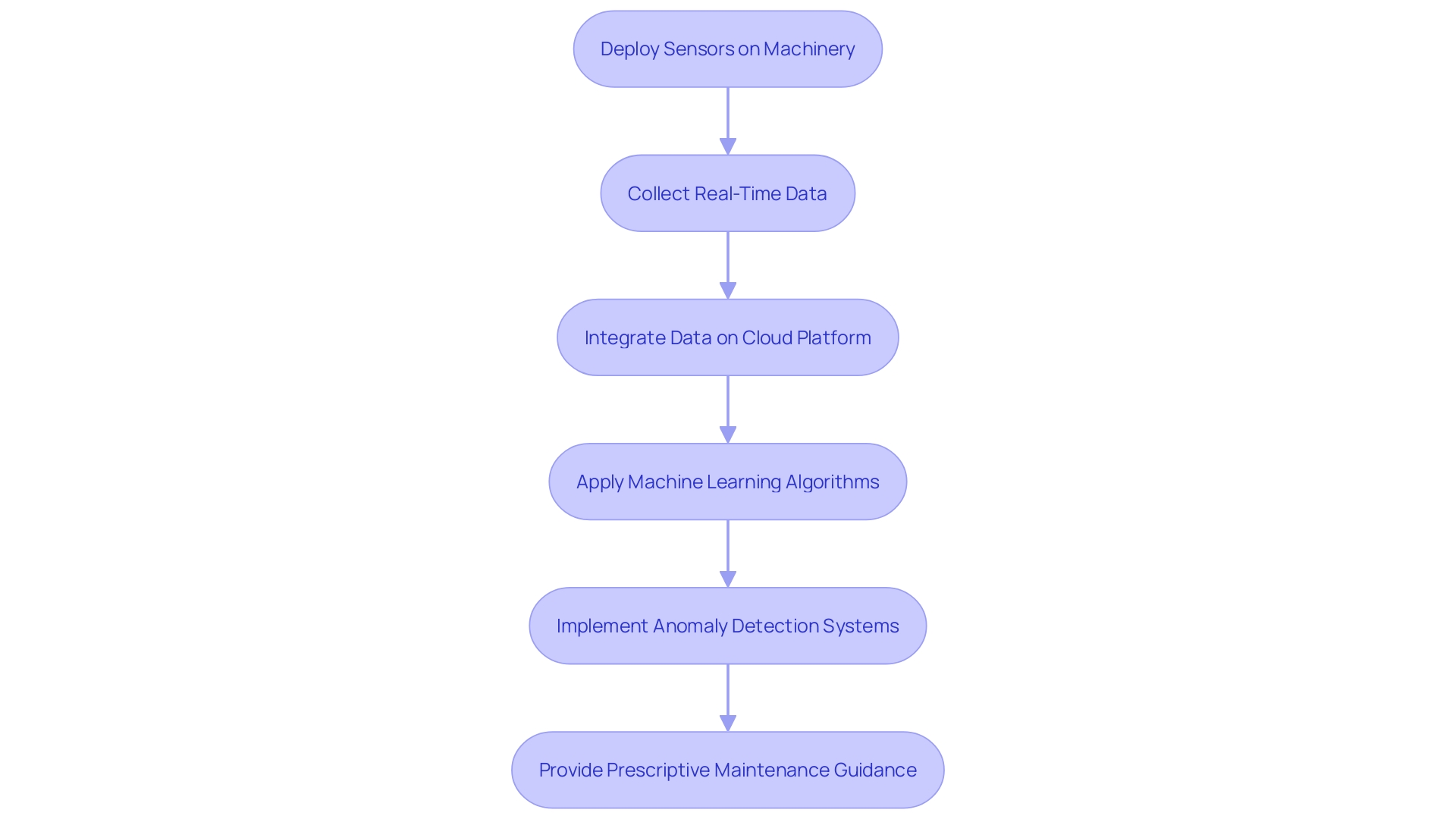

We undertook a meticulous process, starting with the deployment of sensors on critical machinery to collect real-time data, encompassing variables like temperature and power usage. Comprehensive data integration followed, whereby information from these discrete sensors was amalgamated on a cloud platform, leveraged by advanced machine learning algorithms to uncover hidden insights.

Anomaly detection systems applied sophisticated models to snuff out irregularities, preempting machine failures and providing an invaluable lead time for corrective action. This system bestowed calculable and incisive recommendations, empowering maintenance teams with prescriptive guidance. With these proactive procedures in place, the maintenance operations transitioned from a beleaguered, reactive state to one of strategic foresight, aligning with the shift from manual to digitally augmented environments. As manufacturers have been compelled to adopt wide-ranging digital initiatives, from digital twins to AI-enhanced tools, predictive maintenance through IoT articulates the epitome of industry evolution, heralding a new epoch of heightened productivity and operational dexterity.

Benefits of Predictive Maintenance: Real-Life Examples

E-commerce operations have seen a transformative shift through the embrace of predictive maintenance, which employs machine learning and data analysis for several strategic advantages. Foremost among these is the cost savings resulting from proactively identifying and addressing equipment issues. By avoiding unplanned system downtime, companies sidestep costly emergency fixes and mitigate potential revenue losses—outcomes formerly common when equipment would fail without warning.

Moreover, the operational workflow is notably enhanced as predictive insights permit the scheduling of maintenance, thereby decreasing the chance of unscheduled interruptions. Efficiency and productivity ascend, enabling swifter order processing and higher throughput. Concurrently, the customer satisfaction aspect is markedly enhanced since product customization, competitive pricing, and swift delivery—the critical factors driving consumer preferences—can be more consistently assured.

Customers acquire their products without delays or the frustration of cancellations, fostering increased loyalty and encouraging repeat business. Steeped in improvements, these advancements in maintenance stem from the integration of machine intelligence and time series data analyses, which not only capture but also cognitively examine vast volumes of infrastructural data. As businesses face the imperative to integrate disruptive technologies like AI, machine learning, digital twins, and autonomous robots, predictive maintenance serves as a beacon, demonstrating how digital adoption can directly fuel productivity and customer satisfaction in the e-commerce segment.

Conclusion

The transition from reactive to predictive maintenance in the e-commerce sector has demonstrated its potential to enhance operational efficiency. By leveraging advanced digital technologies such as IoT-based predictive maintenance systems, real-time data integration, and machine learning algorithms, businesses can preempt equipment failures and optimize maintenance operations. Predictive maintenance, powered by machine intelligence and data analysis, offers several key benefits.

Firstly, it leads to significant cost savings by proactively identifying and addressing equipment issues, thereby avoiding expensive emergency fixes and revenue losses from unplanned downtime. Secondly, it enhances operational workflow by enabling maintenance scheduling and reducing the chances of unscheduled interruptions. This, in turn, improves efficiency, productivity, and customer satisfaction.

With customized products, competitive pricing, and swift delivery being crucial in the e-commerce landscape, predictive maintenance plays a pivotal role in meeting these expectations. By capturing and analyzing vast amounts of time series data, businesses can consistently assure customers of product availability and timely delivery, fostering increased loyalty and repeat business. Overall, the implementation of predictive maintenance applications in the e-commerce sector represents a transformative shift.

It showcases the power of digital transformation, providing businesses with a strategic edge in a rapidly evolving market. By embracing advanced technologies like AI, digital twins, and machine intelligence, companies can maximize productivity, optimize operations, and deliver exceptional customer experiences. Predictive maintenance serves as a beacon, guiding businesses towards long-term success in the digital era.