Introduction

The article explores the role of IoT consulting companies in the industrial sector's transformation and how they help businesses unlock new opportunities for growth. It discusses the challenges faced by industries adopting the Industrial Internet of Things (IIoT) and how IoT consulting firms navigate complexities such as connectivity and data security.

The article highlights the importance of strategic partnerships and the role of IoT in promoting sustainability and circular business models. Additionally, it presents a case study on leveraging IIoT for manufacturing efficiency and discusses the selection of the right industrial IoT platform for smart manufacturing. The article also delves into data-driven services in the heavy vehicles industry and concludes by emphasizing the transformative approach needed in a data-driven future.

Unlocking New Opportunities for Business Growth

IoT consulting companies are the linchpins in the industrial sector's ongoing transformation, offering the expertise required to harness the full potential of the Industrial Internet of Things (IIoT). As businesses across manufacturing, energy, and healthcare sectors adopt IIoT, they encounter complexities such as connectivity and data security. Adept in navigating these challenges, IoT consulting firms ensure that the integration of IIoT aligns with the company's mission, fortifying their operations and catalyzing innovation.

With the advent of Industry 4.0, IIoT becomes integral to automating and enhancing data exchange across manufacturing and supply chain operations. Consulting firms play a crucial role in actualizing this transition, enabling connectivity and offering insights that drive predictive capabilities and optimization. For example, IoT sensors embedded in products can provide real-time data on usage and maintenance, which companies can leverage to improve customer experiences and develop new business models like product-as-a-service, fostering recurring revenue and stronger customer ties.

Strategic partnerships facilitated by IoT consultants allow businesses to tap into new markets and leverage expertise for mutual growth. As Steve Rogerson discussed with Alistair Fulton, many companies recognize the competitive advantage and financial benefits It brings but lack the in-house skills to develop necessary applications. IoT consulting firms bridge this gap, providing the tools and partnerships needed to expedite success in IoT initiatives.

Moreover, IoT's role in promoting sustainability and circular business models cannot be overstated. By embedding IoT technologies, businesses can monitor and optimize their environmental performance, transitioning towards renewable energy and circular practices that reduce waste and extend product lifecycles. Consequently, It consulting firms are not just enablers of economic growth but also key players in driving sustainable business practices.

Case Study: Leveraging IIoT for Manufacturing Efficiency

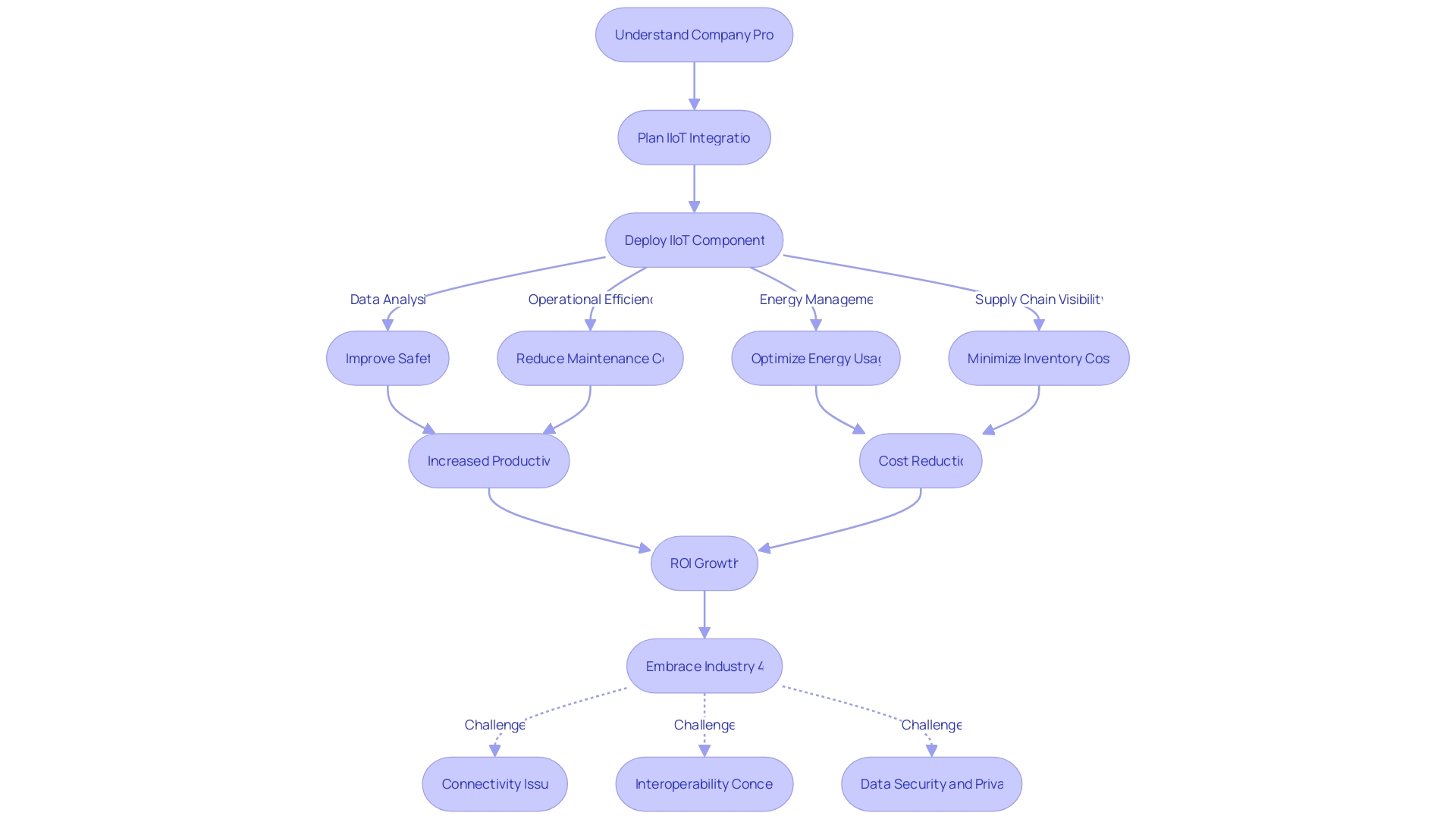

In a recent collaboration with a prominent manufacturing firm, our IoT consulting company took on the challenge of revamping their production processes through Industrial IoT (IIoT) integration. Our detailed case study reveals the transformation from a traditional factory to a smart, connected facility, highlighting the significant strides in operational efficiency. We initiated the project by thoroughly understanding the company's profile, including its industry positioning, headquarters, financials, and workforce size.

The mission was clear: to leverage modern Industry 4.0 technologies, such as advanced data software, to integrate disparate data sources, streamline operations, and bolster overall equipment effectiveness (OEE). The venture involved meticulous planning and deployment of key IIoT components in partnership with seasoned technology providers. This strategic move propelled the company towards sustainable manufacturing, with an impressive 15% boost in productivity and a 90% cost reduction in manual data collection.

The case study showcases the tangible benefits of digitalisation in manufacturing, despite the initial investment and the need for skilled resources for system maintenance and monitoring. It is a testament to the potential of IIoT to not only reduce costs but also to create new, profitable business models and improve safety through environmental and equipment monitoring. Our report underscores the importance of sharing best practices and collaborating to standardize Industry 4.0 implementations, a move that can benefit the entire sector.

Industrial IoT Platform for Smart Manufacturing

Selecting the right industrial IoT platform is a pivotal step in advancing smart manufacturing. This is exemplified by a recent project our IoT consulting firm undertook with a manufacturing client.

We guided them through the intricate process of identifying an IoT platform that not only aligns with their operational needs but also addresses the challenges of connectivity, interoperability, data security, and privacy. Our approach began with a thorough overview of the client's business, evaluating their industry position, operational workflow, and technological infrastructure.

The collaborative effort involved dissecting the data architecture and integrating networked sensors and software, aiming to transition towards a self-regulating system. The goal was to enhance productivity, diminish waste, and bolster overall operational efficacy.

Through this endeavor, we aimed to equip the client with the ability to leverage predictive analytics, thereby facilitating preemptive maintenance and reducing unplanned downtime. In the context of a changing industrial landscape, marked by supply chain complexities and a shift towards digitalization, our client's journey reflects a broader industry movement.

As reported by IOTech's partnership with Advantech, the integration of advanced edge data processing solutions is becoming increasingly essential. It enables real-time data management from myriad endpoints, crucial for modern manufacturing environments that prioritize efficiency and agility. Furthermore, as industry leaders like PTC's Abby Eon and Howard Heppelmann emphasize, the digital transformation journey hinges on breaking down data silos and ensuring accessible, organized, and secure data. This transformation is not solely reliant on cutting-edge technology; it also necessitates a re evaluation of processes and organizational structures to scale effectively. The successful implementation of this IoT platform stands as a testament to the potential of IIoT in revolutionizing industrial settings, making them more connected and responsive to the dynamic demands of Industry 4.0.

Data-Driven Services in the Heavy Vehicles Industry

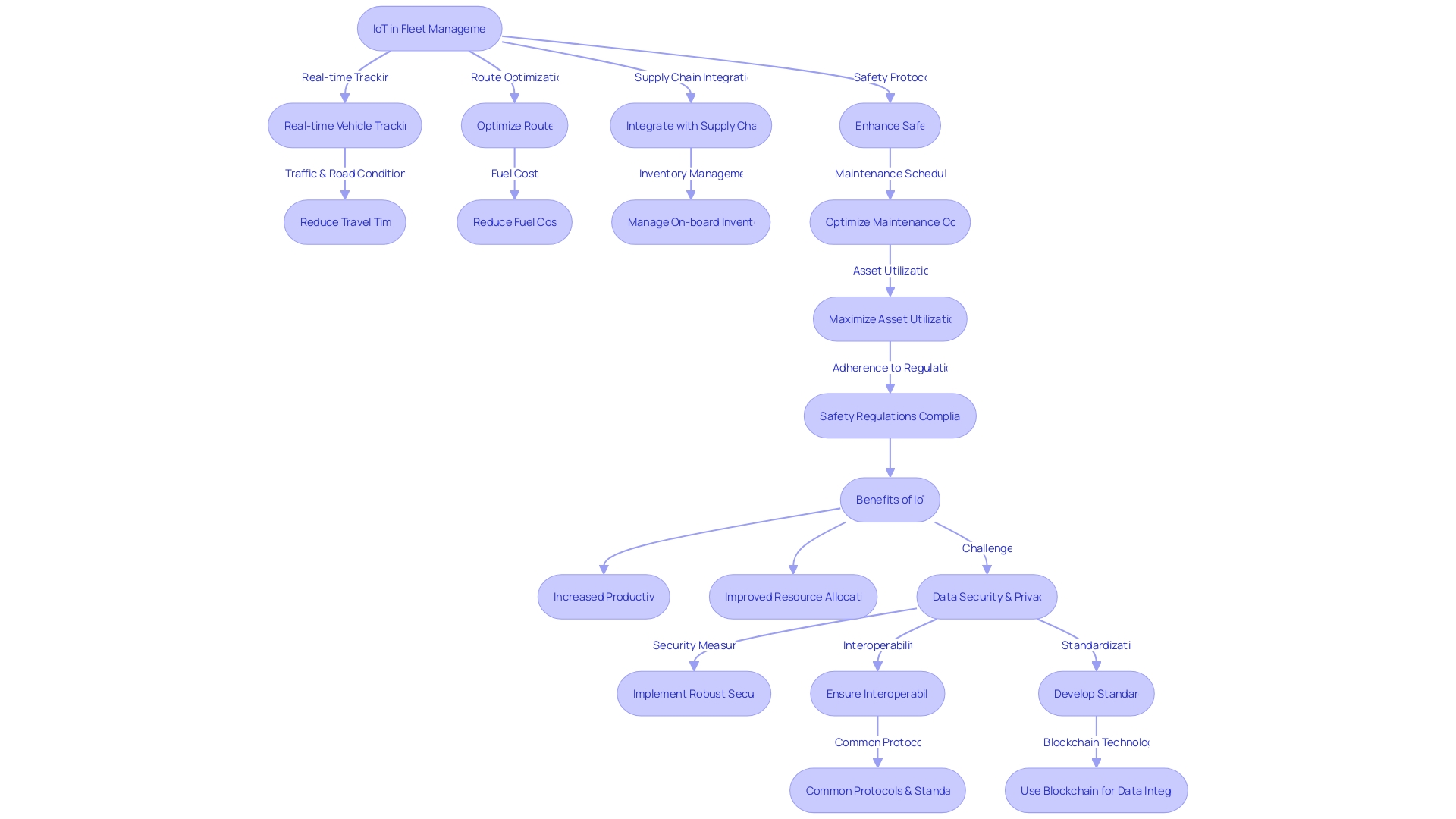

The heavy vehicles industry is at a crossroads with pressing challenges such as optimizing maintenance costs, maximizing asset utilization, and adhering to stringent safety regulations. Leveraging the transformative power of IoT, our consulting firm partnered with a premier heavy vehicles manufacturer to craft cutting-edge data-driven services that effectively tackle these issues. In the pre-IoT era, fleet management relied on rudimentary tools like paper logs and early GPS systems, which led to delays and inaccuracies in crucial data like vehicle location and status.

Maintenance was a reactive process, and there was no efficient method to monitor vehicle health in real time or track fuel consumption and idling times. Now, IoT stands at the forefront of revolutionizing fleet management by enabling real-time tracking, route optimization, integration with supply chains, and enhanced safety protocols. Our collaboration has harnessed IoT to transform fleet operations, turning shipping containers into intelligent agents capable of self-clearing customs and digitalizing end-to-end shipping documents.

The partnership with Pairpoint, Deloitte, and Nexxiot has yielded a service that autonomously verifies the provenance of cargo data, ensuring compliance with trade laws and expediting the digital transformation of the logistics sector. This has led to swifter customs and port authority clearances, thanks to the smart connected sensors and the digital asset broker (DAB) platform, which also facilitates programmable smart contracts to further automate supply chain processes. In the words of industry experts, the balance between innovation and responsibility is paramount.

The automotive industry's data and AI-driven future promises breakthroughs in autonomous driving and vehicle connectivity, while also emphasizing sustainability. With IoT, vehicles are becoming smarter and more eco-friendly, and the driving experience more personalized. As we continue to explore the applications and benefits of IoT in the heavy vehicles industry, it's clear that the technology not only addresses current challenges but also paves the way for a more efficient, safe, and sustainable future.

Transformative Approach in a Data-Driven Future

Harnessing the power of IoT technologies, our consultancy is at the forefront of pioneering data-driven solutions for businesses seeking to thrive in the modern landscape. We delve into the complexities of each company's unique ecosystem, assessing factors such as industry specifics, operational scale, and technological infrastructure.

Our case studies underscore the diversity of our approach, showcasing detailed profiles of businesses from various sectors and their journeys towards integrating IoT solutions. These narratives highlight the mission, strategic insights, and technological partnerships that have propelled them into the era of Industry 4.0, where data architecture and real-time analytics are pivotal.

Our expertise is further exemplified by our grasp of the nuances between Industry 4.0 and the Industrial Internet of Things (IIoT), acknowledging that manufacturers have diverging perspectives on these paradigms. In the realm of IoT, the burgeoning number of connected devices is reshaping supply chains, enhancing transparency and efficiency.

Our insights into this evolution are informed by the latest trends, including the adoption of digital platforms and advanced security measures to maintain data integrity. With the integration of IoT and AI, businesses are poised to unlock innovative services and revenue models, such as predictive maintenance and usage-based offerings, fortifying their competitive edge. As informed by industry leaders, we recognize that the deluge of complex technology must be navigated with precision, ensuring that IoT implementations are strategically aligned with enterprise goals. The transformative potential of IoT is not just in the technology itself but in the actionable insights and operational enhancements that it facilitates for businesses.

Lessons Learned and Best Practices for IIoT Consulting

Gleaning insights from an array of Industrial Internet of Things (IIoT) initiatives, it's evident that the pathway to digital transformation is as diverse as the companies embarking on such journeys. Each case study we've examined offers a panoramic view of the business at hand, shedding light on their unique industry positioning, corporate structure, and strategic objectives. The case studies collectively reveal that there is no one-size-fits-all approach to IIoT; rather, a tailored strategy that aligns with the company's specific goals and resources is crucial.

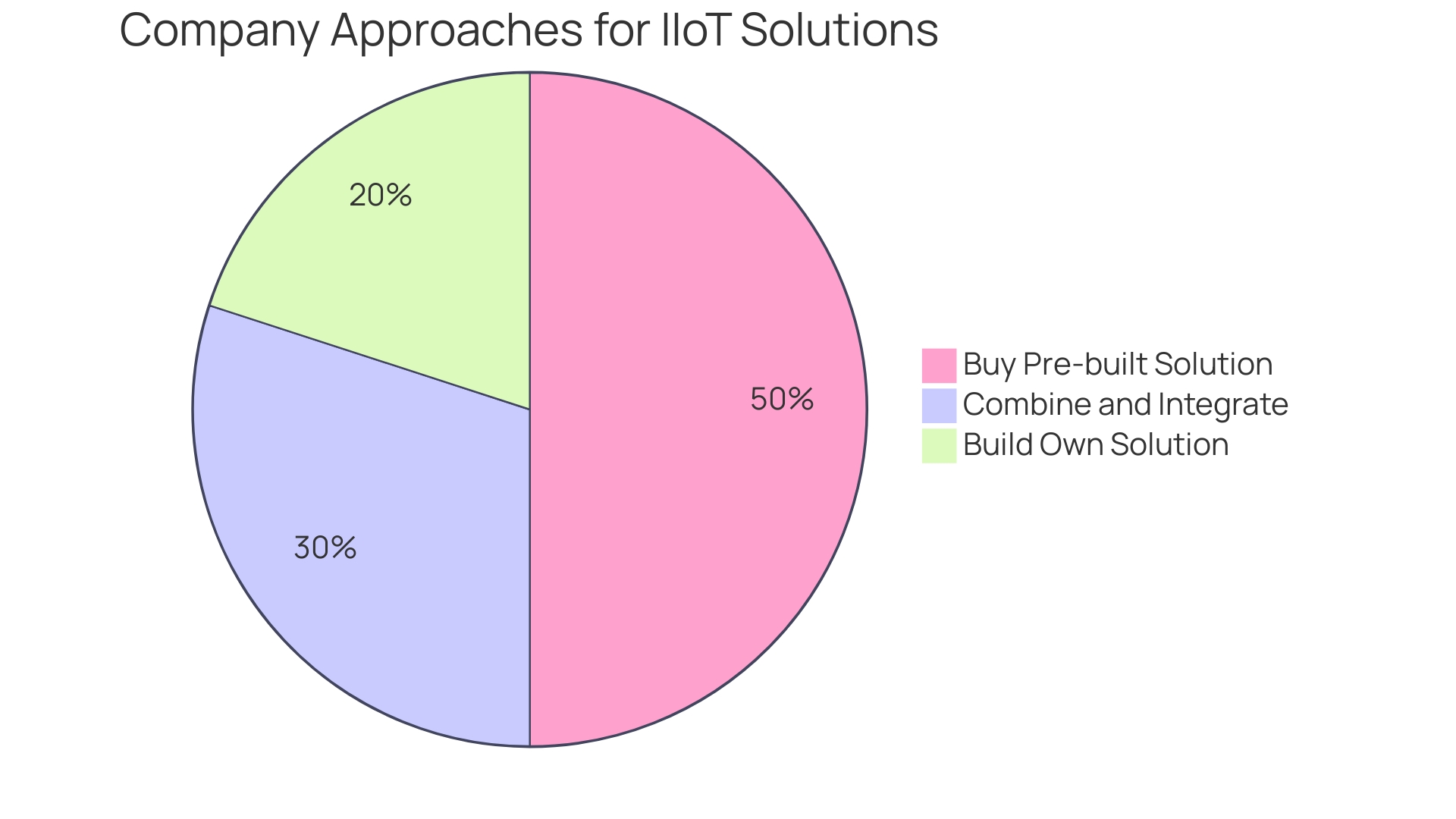

For instance, our insights show that 47% of companies preferred to build their IIoT solutions, with 40% of these reporting that their bespoke systems surpassed expectations. This success is juxtaposed with the challenges of high costs and longer timelines, as one Spanish electronics firm's strategy director pointed out the substantial funds and time required for their project, which is a common hurdle for the build approach. Conversely, the buy approach offers a more plug-and-play solution, with minimal configuration efforts, while the buy-and-integrate option serves those seeking a middle ground, combining off-the-shelf software with some level of customization.

These approaches reflect the diverse perspectives on Industry 4.0 and IIoT, where manufacturers must weigh the benefits of rapid deployment against the desire for tailored solutions that offer competitive advantages and cost savings. The use of modern technology stacks and support technologies enables integration of disparate data sources, leading to improved operational efficiency and key performance indicators. In sum, businesses considering IIoT consulting services should seek partners that not only understand the technical landscape but also appreciate the nuanced decisions that shape successful IIoT deployments.

Conclusion

In conclusion, IoT consulting companies are key players in the industrial sector's transformation. They help businesses unlock new growth opportunities by navigating complexities like connectivity and data security. Strategic partnerships facilitated by IoT consultants enable businesses to tap into new markets and promote sustainability.

Leveraging IIoT for manufacturing efficiency has led to significant strides in operational efficiency. Selecting the right industrial IoT platform is crucial for advancing smart manufacturing. In the heavy vehicles industry, IoT-driven services have transformed fleet operations, making them more efficient, safe, and sustainable.

In a data-driven future, IoT consultancy firms pioneer innovative solutions that help businesses thrive. Tailored strategies considering specific goals and resources are vital for successful IIoT deployments. Businesses should seek partners who understand the technical landscape and appreciate nuanced decisions shaping successful implementations.

Overall, IoT consulting companies play a vital role in driving the industrial sector's transformation. They offer expertise in harnessing the full potential of IIoT while promoting sustainability. The transformative power of IoT lies not only in the technology but also in actionable insights and operational enhancements it facilitates for businesses.

Contact our team of IoT experts today to unlock the full potential of IoT for your business!